Aluminium & Aluminium Alloys Welding Wires

Aluminium & Aluminium Alloys Welding Wires

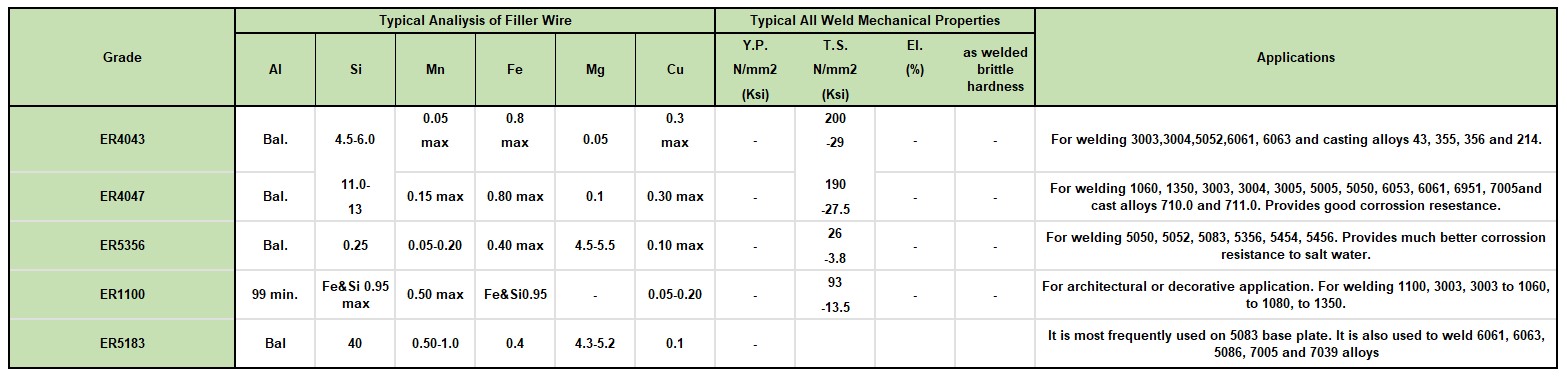

CLASSIFICATION : AWS A/SFA 5.10

KEY FEATURES :

1) Excellent feedability with cansistent welding performance

2) High corrosion resistance

3) Radiographic weld quality

I) ER 1100 CLASSIFICATION : AWS A/SFA 5.10:

Download Product Details

Chemical Composition of ER 1100 Wire:

Si + Fe = 0.95 max

Cu= 0.50.020

Mn= 0.05 max

Zn= 0.10 max

Ti= 0.20 max

Be= 0.0003 max

Al= 99.0 min

TYPICAL APPLICATION OF ER 1100 WIRE (MIG & TIG):

1) Welding of 1XXX series and commercially pure aluminium

2) For Al 99.8, Al 99.7, Al 99.5, E-Al

3) Tanks, brackets, bus bodies

II) ER 4043 CLASSIFICATION : AWS A/SFA 5.10:

Download Product Details

Chemical Composition of ER 4043 Wire:

Si = 4.5-6.0

Fe= 0.8 max

Cu= 0.3 max

Mn= 0.05 max

Mg= 0.05 max

Zn= 0.10 max

Ti= 0.20 max

Al= Bal.

TYPICAL APPLICATION OF ER 4043 WIRE (MIG & TIG):

1) Welding of wrought and cast Al alloy with Si up to 7%

2) Suitable for Al-Si and Al-Mg-Si alloys

3) Ship Building, mobile Machinery

4) Automotive, General Fabrication

5) Welding of similar grade Al alloy in the form of pipe, plate, forging and casting

For welding 3003,3004,5052,6061, 6063 and casting alloys 43, 355, 356 and 214.

III) ER 5356 CLASSIFICATION : AWS A/SFA 5.10:

Download Product Details

Chemical Composition of ER 5356 Wire:

Si= 0.25 max

Fe= 0.40 max

Cu= 0.10 max

Mn= 0.05-0.20

Mg= 4.5-5.5

Cr= 0.05-0.20

Zn= 0.10 max

Ti= 0.06-0.20

Al= Bal.

TYPICAL APPLICATION OF ER 5356 WIRE (MIG & TIG):

1) Welding of similar composition Al- Mg, Al-Mg- Zn and Al-Mg- Si alloys

2) automotive , marine application

3) Structural Fabrications

4) Welding Al alloys containg more than 3% Mg

For welding 5050, 5052, 5083, 5356, 5454, 5456. Provides much better corrossion resistance to salt water.

IV) ER 5183 CLASSIFICATION : AWS A/SFA 5.10:

Download Product Details

Chemical Composition of ER 5183 Wire:

Si= 0.40 max

Fe= 0.40 max

Cu= 0.10 max

Mn= 0.5-1.0

Mg= 4.3-5.2

Cr= 0.05-0.25

Zn= 25 max

Ti= 0.15 max

Al= Bal.

TYPICAL APPLICATION OF ER 5183 WIRE (MIG & TIG):

1) Welding of high strengh Al alloys

2) Automotive, Marine application

3) Structural fabrication

4) Application where high strengh, high impact fracture toughness and exposure to corrosive enviroment are important

FIt is most frequently used on 5083 base plate. It is also used to weld 6061, 6063, 5086, 7005 and 7039 alloys

V) ER 4047 CLASSIFICATION : AWS A/SFA 5.10:

Download Product Details

Chemical Composition of ER 4047 Wire:

Si= 11.0-13.0

Fe= 0.8

Cu= 0.30

Mn= 0.15

Mg= 0.10

Zn= 0.20

Al= Bal.

TYPICAL APPLICATION OF ER 4047 WIRE (MIG & TIG):

1) Welding of wrought and cast Al alloy with Si up to 11%

2) Suitable for Al-Si and Al-Mg-Si alloys

3) Ship Building, mobile Machinery

4) Automotive, General Fabrication

5) Welding of similar grade Al alloy in the form of pipe, plate, forging and casting

For welding 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005and cast alloys 710.0 and 711.0. Provides good corrossion resestance.