Mild Steel

Swastik Weld Make Welding Wire GMAW/GTAW (MIG & TIG) for Carbon Steel

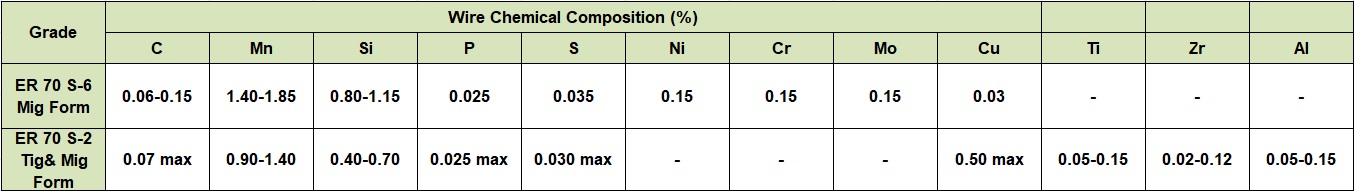

Classification: AWS A/SFA 5.18

KEY FEATURES:

1) C-Mn steel solid wire and low alloy wires

2) Uniform copper coating

3) Can be use with 100% CO, Ar+CO2

4) Higher level of de-oxidizers makes it suitable for applications where dirt, rust or mill-scale is present

5) Radiographic quality weld

I) ER 70S-6 CLASSIFICATION: AWS A/SFA 5.18:

Download Product Details

Chemical Composition of ER 70S6 Wire:

C= 0.06-0.14

Mn= 1.40-1.60

Si= 0.80-1.0

S= 0.025 max

Ni= 9.4

P= 0.025 max

Cu= 0.50 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 500-640

EL%= 24 min

TYPICAL APPLICATION OF 70S-6 :

1) Construction and miming equipment

2) Pressure vessels, LPG Cylinders

3) Root pass pipes welding, Tanks, Structural steel components, Thin sheet metal, Auto body and general fabrication

II) ER 70S-2 CLASSIFICATION: AWS A/SFA 5.18:

Download Product Details

Chemical Composition of ER 70S-2 Wire:

C= 0.07 max

Mn= 0.90-1.40

Si= 0.40-0.70

Ti= 0.05-0.15

Zr= 0.02-0.12

Al= 0.05-0.15

Cu= 0.50 max

S= 0.030 max

P= 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 420 min

EL%= 22 min

TYPICAL APPLICATION OF 70S-2 :

1)Welding of pressure vessel, Boilers involving unalloyed and micro-alloyed structural steels with specified UTS up to 520Mpa

2) High quality pipe welding of mild and medium tensile steels

3) Best suited for single side, melt through welding

Swastik Weld Make Welding Wire GMAW/GTAW (MIG & TIG) for Low Alloy Steel

KEY FEATURES

1) Copper coated low alloy steel solid wire and low alloy wires

2) Uniform copper coating

3) Careful control of pre-heat, interpass temperature & PWHT is essential to avoid cracking

4) Higher level of de-oxidizers makes it suitable for applications where dirt, rust or mill-scale is present

5) Radiographic quality weld

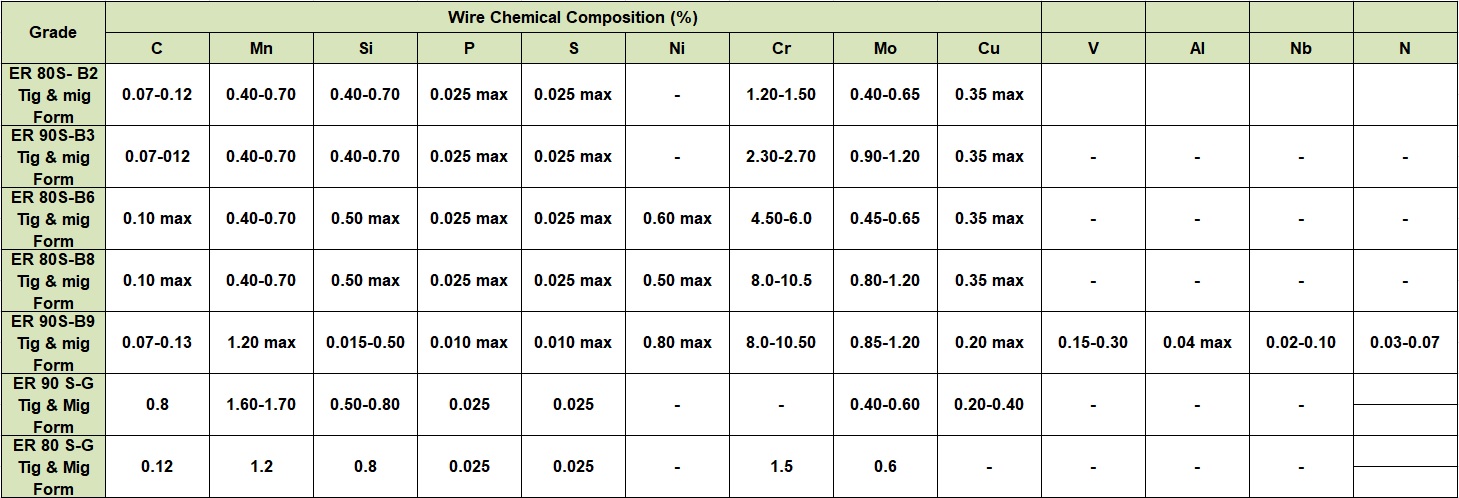

I) ER 80SB-2 CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 80S-B2 Wire:

C= 0.07-0.12

Mn= 0.40-0.70

Si= 0.40-0.70

Cr= 1.20-1.50

Mo= 0.40-0.65

Cu= 0.35 max

S= 0.025 max

P= 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 550 min

EL%= 19 min

TYPICAL APPLICATION OF 80S-B2 :

1) Typical 1.25 Cr-0.5 Mo weld deposit

2) Welding of 0.5Cr-0.5Mo, 1Cr-0.5Mo and 1.25Cr-0.5Mo steel pipes, plates and casting

3) Can be used for joining dissimilar combinations of Cr-Mo and carbon steels

4) suitable for ASTM A 199-76, A 200-75, A 213-76D, A335 Gr.P11, A369-76, A387 Gr.B, DIN 15CrMo3

II) ER 90SB-3 CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 90S-B3 Wire

C= 0.07-0.12

Mn= 0.40-0.70

Si= 0.40-0.70

Cr= 2.30-2.70

Cu= 0.35 max

S= 0.025 max

P= 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 620 min

EL%= 17 min

TYPICAL APPLICATION OF 90S-B3:

1) Typical 2.25 Cr-1 Mo weld deposit

2) Welding of 2.25Cr-0.5Mo and 2.25Cr-1Mo type creep resistant steels

3) Joining ASTM A 335 Gr.P22, A 387 Gr.22 materials

4) Refineries, petrochemical and fertilizers plant

5) Joining of P5A materials

6) Cr-Mo and Mo-V bearing steels for high temperature applications

7) Suitable for 12CrMo9-10, 10CrSiMoV7 German steels

III) ER 80S-B6 CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 80S-B6 Wire

C= 0.10 max

Mn= 0.40-0.70

Si= 0.50 max

Cr= 4.50-6.0

Mo= 0.45-0.65

Ni= 0.60 max

Cu= 0.35 max

S= 0.025 max

P= 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 560 min

EL%= 17 min

TYPICAL APPLICATION OF 80S-B6:

1)Typical 5 Cr-0.5 Mo weld deposit

2) Welding of 5 Ct-0.5 Mo Creep resistant steels and equivalent grades

3) Application in power generatoin, ammonia synthesis plants and petrochemical industries

4) Joining P58/T5 materials of similar composition

5) Joining P5B materials e.g. SA 336/336M Gr.F5, SA 387/387M Gr.5

IV) ER 80S-B8 CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 80S-B8 Wire

C= 0.10 max

Mn= 0.40-0.70

Si= 0.50 max

Cr= 8.0-10.5

Mo= 0.80-1.20

Ni= 0.50 max

Cu= 0.35 max

S= 0.025 max

P= 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 550 min

EL%= 17 min

TYPICAL APPLICATION OF 80S-B8:

1)Typical 9 Cr-1 Mo weld deposit

2) Welding of 9Cr-1Mo type and equivalent materials in pipe and tube forms

3) Welding of ferritc martensutic chrome steels

4) For general corrosion and heat resistance application

6) Joining P9/T9 materials of similar composition

7) Application in power plants, Oil refineries, Chemical and petrochemical industries

V) ER 90S-B9 CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 90S-B9 Wire

C= 0.07-0.13

Mn= 1.20 max

Si= 0.15-0.50

Cr= 8.0-10.50

Mo= 0.85-1.20

Ni= 0.80 max

V-0.15-0.30

Cu= 0.20 max

Al= 0.04 max

N= 0.03-0.07

S= 0.010 Max

P= 0.010 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 620 min

EL%= 16 min

TYPICAL APPLICATION OF 90S-B9:

1) Typical 9Cr-1Mo-V-Nb type weld deposit

2) Suitable for welding of Cr-Mo-V-Nb steels such as P91, T91 and F91

3) Suitable for material 1.4903, SA 387 Gr.91, SA 213 T91, SA 335 P91

4) For heavy wall components such as headers, main steam piping and turbine rotors in power generation plants

VI) ER 80S-G CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 80S-G Wire

C= 0.09

Mn= 1.6

Si= 0.6

Mo= 0.4

S= 0.01

P= 0.01

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 600

EL%= 24

TYPICAL APPLICATION OF 80S-G :

1) Welding of Mn-0.5 steel

2) Pipelines and pressure vessels with operating temperatures of about 500 C

3) Suitable wide range of low alloy Cr-Mo base metals

VII) ER 90S-G CLASSIFICATION: AWS A/SFA 5.28

Download Product Details

Chemical Composition of ER 90S-G Wire

C= 0.09

Mn= 1.6

Si= 0.6

Mo= 0.4

S= 0.01

P= 0.01

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, Mpa= 650

EL%= 25

TYPICAL APPLICATION OF 90S-G :

1) Welding high sulfur bearing free machining steels, medium carbon steels, 0.5 Mo steels and high temperature resistant steels

2) Pipelines and pressure Vessels with operating temperatures of about 500 C

3) Repair of meduim strengh steels castings